types of fence panels

-

Affordable Steel Fence Posts Available for Purchase Now

steel fence posts for sale ....

-

5x5 post caps

The Rise of 5x5 Post Caps A Perfect Blend of Functionality and Aesthetics In recent years, the world...

-

Designing a Modern Single Swing Iron Gate for Your Entrance

The Elegance and Functionality of a Single Swing Iron Gate In the realm of home design and outdoor a...

-

200 ft of chain link fence

The Versatility of 200 Feet of Chain Link Fence When it comes to securing spaces, whether residentia...

-

Durable 48 Inch Chain Link Fencing for Enhanced Security and Privacy Solutions

Understanding the 48% Chain Link Fence A Blend of Functionality and Aesthetics When it comes to secu...

-

chicken wire 3 4 inch

The Versatility of Chicken Wire A Guide to Using 3x4 Inch Mesh Chicken wire, also known as poultry n...

-

Beveiligingshekken voor bouwplaatsen effectieve oplossingen voor veiligheid en bescherming

Builders Security Fencing Een Essentiële Oplossing voor Bouwplaatsen In de wereld van de bouw is vei...

-

60cm Poultry Netting Mesh for Fencing, Gardening, and DIY Projects, Durable and Flexible.

Chicken wire, also known as poultry netting, is a versatile and widely used material in various appl...

-

1.8 m round fence posts

Exploring the Benefits of 1.8m Round Fence Posts When it comes to fencing options for agricultural,...

-

1 ft chicken wire

The Versatility of 1% Chicken Wire An Essential Tool for Home and Garden In the world of gardening,...

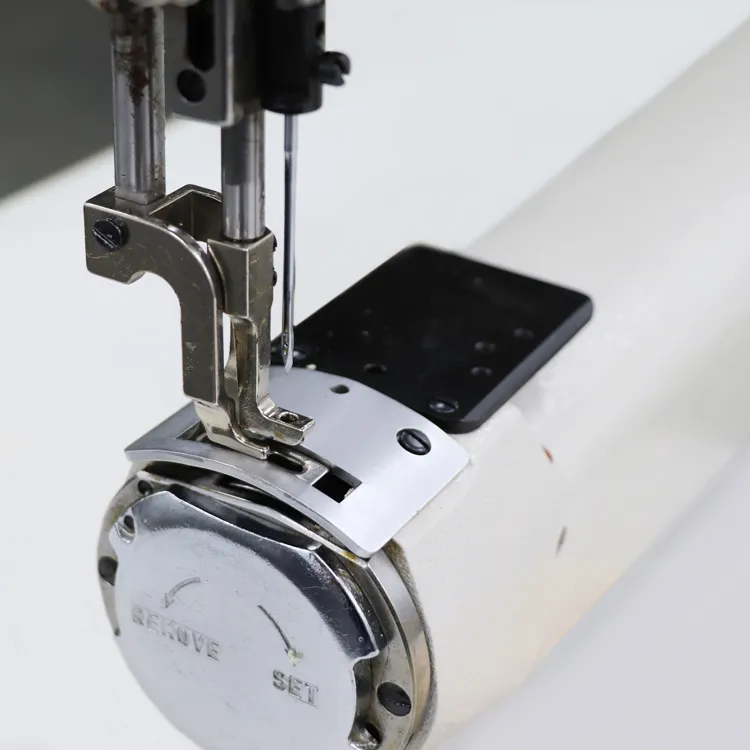

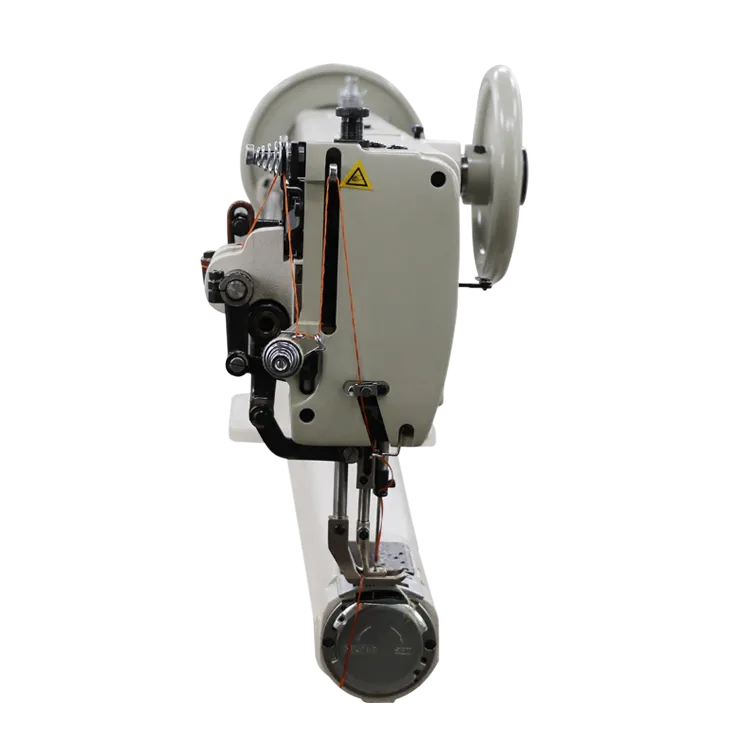

These machines are capable of sewing at much faster speeds than traditional sewing machines, increasing productivity and reducing production times These machines are capable of sewing at much faster speeds than traditional sewing machines, increasing productivity and reducing production times

These machines are capable of sewing at much faster speeds than traditional sewing machines, increasing productivity and reducing production times These machines are capable of sewing at much faster speeds than traditional sewing machines, increasing productivity and reducing production times